RISK Assessment Program

Injury Prevention Education

Truly effective safety programs do not come easily. As with any other business objective, keeping hardworking employees safe will come only with intelligent, aggressive, persistent program management. When it comes to personal protective equipment (PPE), if the equipment is used incorrectly, or not appropriate for the hazard or task, your chance of successfully preventing painful and costly injury is significantly diminished. Also keep in mind that NO protective product works if it is not worn by the people you’re trying to protect.

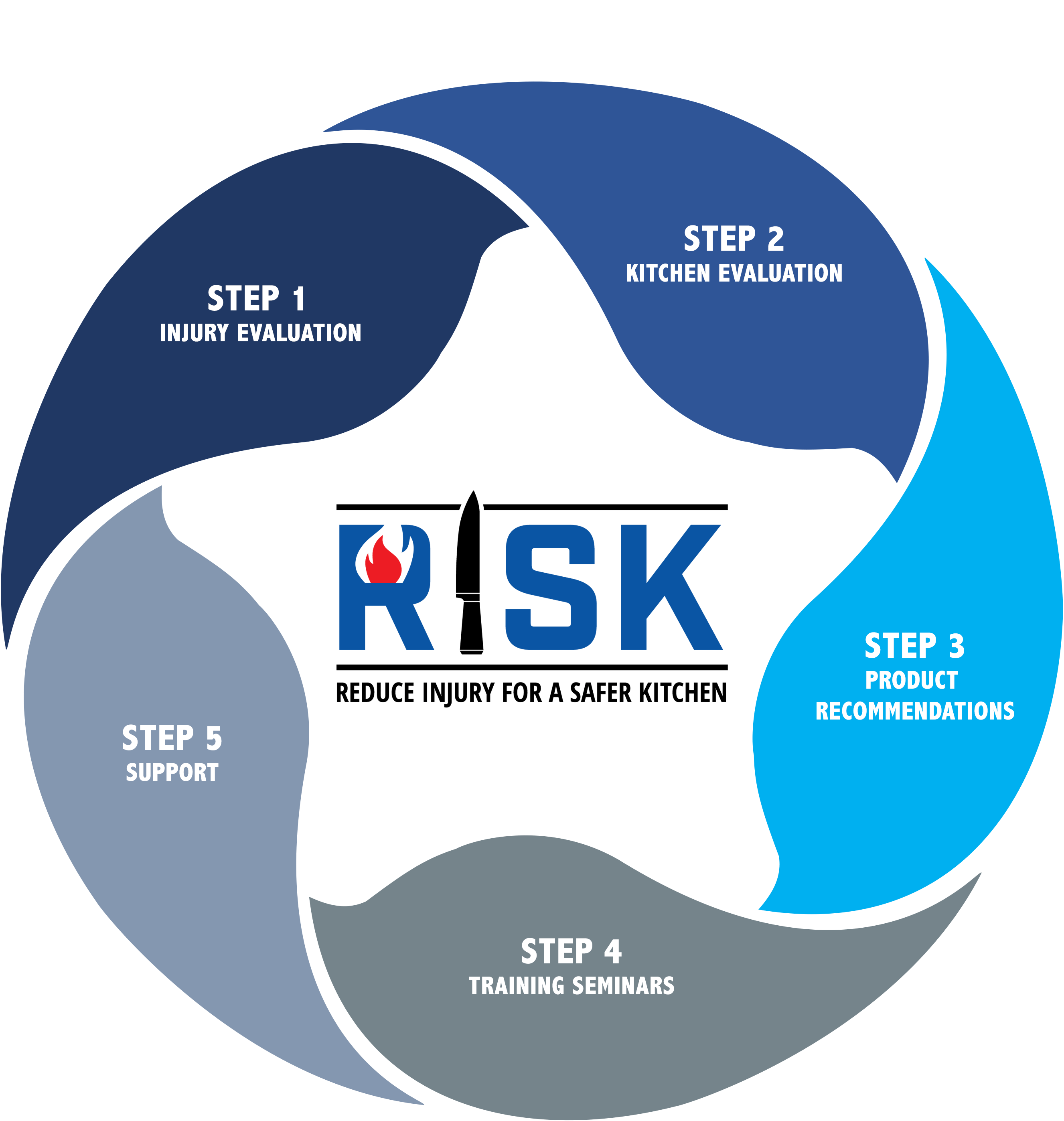

At Tucker Safety, we developed the RISK ASSESSMENT PROGRAM to offer customers a logical, efficient and effective way to approach workplace safety for the commercial kitchen, ways to involve the people most at risk and who are often the first to recognize hazards, and reduce Worker’s Compensation claims.

The Tucker RISK Assessment Program has helped many foodservice operators/owners evaluate their own kitchen environments and ultimately avoid accidents or injuries before they occur, contributing significantly to worker morale as well as the bottom line. This program can do the same for your business, whether you manage one or many locations.

The Tucker RISK Assessment Program is comprised of the following steps:

Step 1 – Injury Evaluation:

We work with you to review past burn and cut injures, human factors, current safety practices and personal protective equipment (PPE) being used. We give you our analysis, conclusions and recommendations based on those findings and our expertise in foodservice operations for the prevention of future injury.

Step 2 – Kitchen Evaluation:

This entails an evaluation of equipment type and position as well as determining hot spots, traffic patterns and other hazards. Each work area and equipment configuration poses different PPE needs such as fabric, temperature, insulators, wearability, washability and steam/vapor protection, etc. During the evaluation, we make note of safety training gaps or unmet safety needs and share those findings as well.

Step 3 – Product Recommendations:

After we study your injury history, equipment in use and your kitchen layout, we will present you with our recommendations (both product and process) and an explanation of why we chose each piece. Our goal is to maximize safety, efficiency and value for your business.

Step 4 – Training Seminars:

In partnership, we then train your managers and their team in proper use of each garment, product labeling, good safety practices, and injury prevention.

Step 5 – Support:

Safety is both a goal and a process. We offer continuing services of evaluating safety performance, procedural or material recommendations, safety training, and should you need it, our complete support in any regulator issues that may arise.

Make sure your kitchen has the right hand protection for improving safety and cost performance. Request your free RISK Assessment Program review today.